A fully integrated site, from raw materials to finished products.

Workshops

Boilermaking

Machining

Stamping and extrusion

Welding

Robotic laser cutting

Storage, packaging, shipping

Expansion joint

Additional operations

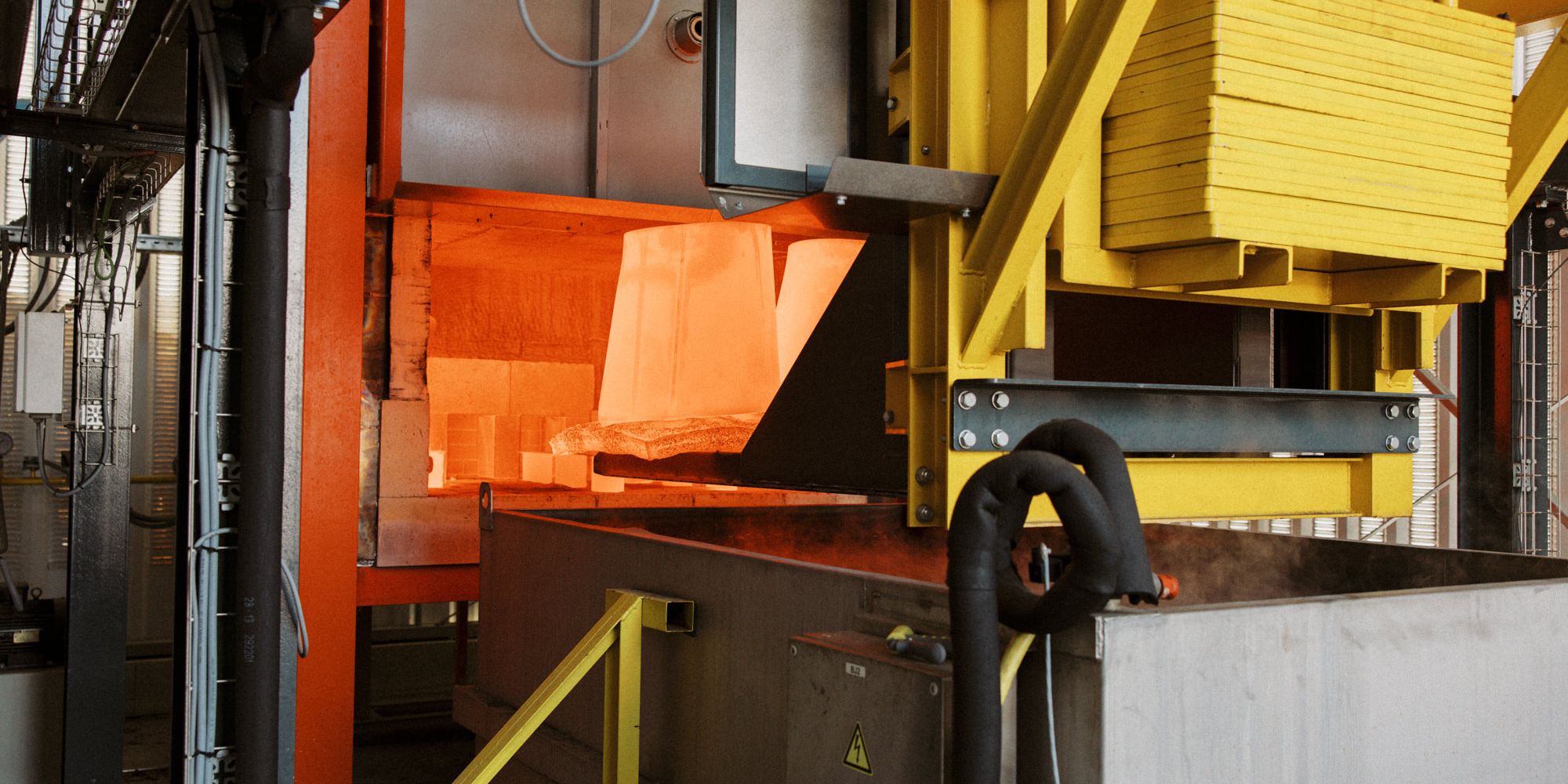

Heat treatment

Pickling

Non-destructive testing

Digital radiography for weld inspection,

Hardness,

Spectrometry,

Dye penetrant inspection.

Certifications

ISO 9001:2015 TéléchargerDESP 2014/68/UE - Module H TéléchargerDESP 2014/68/UE - Module D1 TéléchargerPED 2014/68/UE Télécharger

En cours : EN 19443 et EN 9100